Noah Clay ’97 is a guy who likes to put things into simple terms. You might say he likes to cut things down to size – both in terms of his work and his nature.

Ask him how big a nanometer is and he sets a pencil on the table. Then he asks you to picture the entire continental U.S. and imagine that pencil sitting in it.

It’s less than a speck … and about as big as the units Clay works with as a technical staff member at the Cornell University Nanoscale Science and Technology Facility.

Clay has been using atoms as building blocks for the last decade, first with a Silicon Valley startup, then as nano-fabrication manager at Harvard University’s Center for Nanoscale Systems and now at Cornell.

Essentially, by dissecting the proverbial mouse trap down to its smallest units — atoms are one billionth of a meter in size — it can be built better.

Clay and his colleagues act as advisors, designers and facilitators for more than 700 clients who use the facility for research and development. That’s a lot of different mousetraps.

“I love the variety of work that I have here,” Clay says.

His personal interest is in biomarkers, or tiny signals our bodies emit that might help doctors better monitor or predict someone’s health.

Nanotechnology can help create a device that reads biomarkers in real time, says Clay, whose father passed away from lung cancer.

It was his experience in the hospital waiting for test results that inspired him. He sits on the scientific advisory board of Vista Therapeutics, a spinoff of the Harvard nanotech lab that focuses on better real-time health monitoring.

Biomarkers can, for example, help predict heart attacks, but they have other applications as well. Again, to make a complicated concept simple, Clay picks up a whiteboard eraser in his hand.

“Something that big in the field running on a cell phone battery could diagnose various diseases in a remote village” using biomarkers, Clay says, likening it to fitting an entire laboratory on a computer chip. Nanotechnology makes it possible for something the size of a Blackberry to make the world better.

“My take on technology and efficiency is you’re really just making things better,” Clay simplifies. For example, the first computers used enough electricity to power a small town. “You definitely have more computing power than that in your iPod.

“All these little gains are in the interest of efficiency,” says Clay. These tiny developments also attract big business interested in the biological, electronic and other applications of nanotechnology.

Nanotech research has exploded in recent years. To give it some perspective, Clay remembers Harvard’s facility had 300 users when he started there. After three years, that number had climbed to more than 1,100.

Obviously, there is a seemingly endless bounty of discoveries to be made. Less obvious is the use for things that have already been created.

Some may take a while to come to fruition, says Clay. As an example, light-emitting diodes or LEDs have numerous applications today — particularly in cell phone and other video displays — but no one knew what to do with them in the 1960s when they were developed.

A lot of users are looking for the next LED, the next thing that changes our lives, Clay says. Many are venture capitalists or representatives of major corporations. For instance, Xerox and Corning have created prototypes at Cornell.

Their projects can take anywhere from a few weeks to a few years, depending on results. The costs can easily range in the millions of dollars.

A look at the intricate machinery in the clean room in the basement of Duffield Hall at Cornell hints that the processes going on here aren’t cheap.

There are ultra-powerful microscopes that take up entire rooms. They reveal atoms and their electrons on computer screens that constantly flicker and spit out digital numbers that are perpetually spinning.

There are ultra-powerful microscopes that take up entire rooms. They reveal atoms and their electrons on computer screens that constantly flicker and spit out digital numbers that are perpetually spinning.

There are vacuum chambers that reach from floor to ceiling with seemingly countless plugs and pipes sticking out of them.

Cornell University students, staff and “users” or clients mill about in white Tyvek suits, giving the area a deep-space vibe.

And it’s loud in here.

Some of these chambers are kept at temperatures close to absolute zero. It slows the atoms down so they can be more easily observed and manipulated.

The result is a steady whirring that quiets to a sterile hum the more time you spend here.

Clay has worked in this type of environment since the late 1990s. After earning his physics degree at Oswego, Clay went on to study electrical engineering at Tufts University.

His first two employers, Goodrich Corp. in New Jersey and Infinera in California, used nanotechnology to produce computer chips. From there he went to Harvard, where he managed a facility similar to Cornell’s.

“There are certain times over the course of your education you think, ‘I’m never going to use this,’” Clay says. “All those calculus and physics courses I took [at Oswego], I use every day in my job.”

Every day he is on the brink of a breakthrough and it’s a thrill he can look forward to each morning.

After all, his next tiny discovery could be the next big thing.

You might also like

More from Featured Content

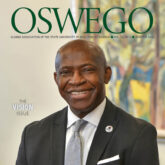

Vision for the Future

VISION for the Future Peter O. Nwosu began his tenure as the 11th president of SUNY Oswego, building on the solid …

Envisioning the Potential in All Students

ENVISIONING the Potential in All Students Educator donates $2 million in recognition of his Oswego education, in support of future teachers Frank …

A Vision of Support

A VISION of Support Award-winning principal makes an impact on her school through her positivity and commitment When Nicole Knapp Ey ’02 …